无铅焊膏印刷模板开口设计推荐规范

■宽厚比=开口的宽度(W)/模板的厚度(T)>1.6

■ 面积比=开口面积(LXW)/孔壁的面积[2*(L+W)*T]>0.71

1. 一般印焊膏模板开口尺寸及厚度

|

元件类型 |

PITCH |

焊盘宽度 |

焊盘长度 |

开口宽度 |

开口长度 |

模板厚度 |

宽度比 |

面积比 |

|

PLCC |

1.27mm |

0.65mm |

2.0mm |

0.60mm |

1.95mm |

0.15-0.25mm |

2.3-3.8 |

0.88-1.48 |

|

(50mil) |

(25.6mil) |

(78.7mil) |

(23.6mil) |

(76.8mil) |

(5.91-9.84mil) |

|||

|

QFP |

0.635mm |

0.635mm |

0.635mm |

0.635mm |

0.635mm |

0.635mm |

1.7-2.0 |

0.71-2.0 |

|

(25mil) |

(13.8mil) |

(59.1mil) |

(11.8mil) |

(57.1mil) |

(5.91-7.5mil) |

|||

|

QFP |

0.50mm |

0.254-0.33mm |

1.25mm |

0.22-0.25mm |

1.2mm |

0.125-0.15mm |

1.7-2.0 |

0.69-0.83 |

|

(20mil) |

(10-13mil) |

(49.2mil) |

(9-10mil) |

(47.2mil) |

(4.92-5.91mil) |

|||

|

QFP |

0.40mm |

0.25mm |

1.25mm |

0.2mm |

1.2mm |

0.10-0.125mm |

1.6-2.0 |

0.68-0.86 |

|

(15.7mil) |

(9.84mil) |

(49.2mil) |

(7.87mil) |

(47.2mil) |

(3.94-4.92mil) |

|||

|

QFP |

0.30mm |

0.20mm |

1.00mm |

0.15mm |

0.95mm |

0.075-0.125mm |

1.50-2.0 |

0.65-0.86 |

|

(11.8mil) |

(7.87mil) |

(39.4mil) |

(5.91mil) |

(37.4mil) |

(2.95-3.94mil) |

|||

|

0402 |

|

0.50mm |

0.65mm |

0.45mm |

0.6mm |

0.125-0.15mm |

|

0.84-1.00 |

|

|

(19.7mil) |

(25.6mil) |

(17.7mil) |

(23.6mil) |

(4.92-5.91mil) |

|||

|

0201 |

|

0.25mm |

0.40mm |

0.23mm |

0.35mm |

0.075-0.125mm |

|

0.66-0.89 |

|

|

(9.84mil) |

(15.7mil) |

(9.06mil) |

(13.8mil) |

(2.95-3.94mil) |

|||

|

BGA |

1.27mm |

φ0.80mm |

|

φ0.75mm |

|

0.15-0.20mm |

|

0.93-1.25 |

|

(50mil) |

(31.5mil) |

|

(29.5mil) |

|

(5.91-7.87mil) |

|||

|

U BGA |

1.00mm |

φ0.38mm |

|

φ0.35mm |

0.35mm |

0.115-0.135mm |

|

0.67-0.78 |

|

(39.4mil) |

(15.0mm) |

|

(13.8mil) |

(13.8mil) |

(4.53-5.31mil) |

|||

|

U BGA |

0.50mm |

φ0.30mm |

|

φ0.28mm |

0.28mm |

0.075-0.125mm |

|

0.69-0.92 |

|

(19.7mil) |

(11.8mm) |

|

(11.0mil) |

(11.0mil) |

(2.95-3.94mil) |

|||

|

Flip Chip |

0.25mm |

0.12mm |

0.12mm |

0.12mm |

0.12mm |

0.08-0.10mm |

|

1.0 |

|

(10mil) |

(5mil) |

(5mil) |

(5mil) |

(5mil) |

(3-4mil) |

|||

|

Flip Chip |

0.20mm |

0.10mm |

0.10mm |

0.10mm |

0.10mm |

0.05-0.10mm |

|

1.0 |

|

(8mil) |

(4mil) |

(4mil) |

(4mil) |

(4mil) |

(2-4mil) |

|||

|

Flip |

0.15mm |

0.08mm |

0.08mm |

0.08mm |

0.08mm |

0.025-0.08mm |

|

1.0 |

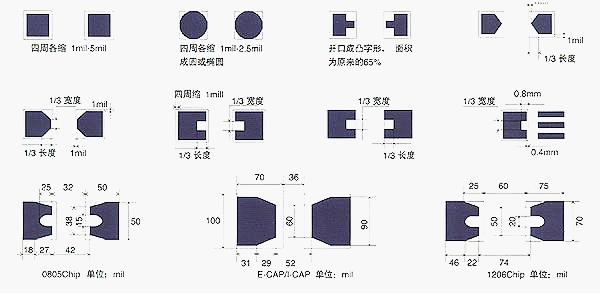

2. Chip件开口修改方案

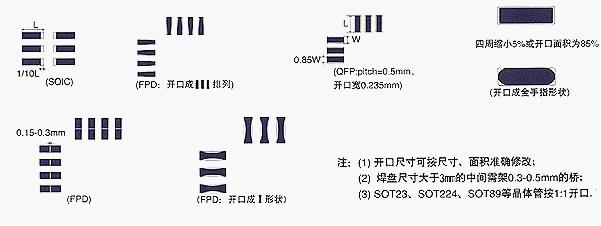

3. IC开口修改方案

|

|

4.制造方法:一般采用激光切割加电化学抛光(Laser + Electroplish )工艺。如果开口宽厚比和面积比接近门限值,建议采用电铸(Electroform)工艺制造。